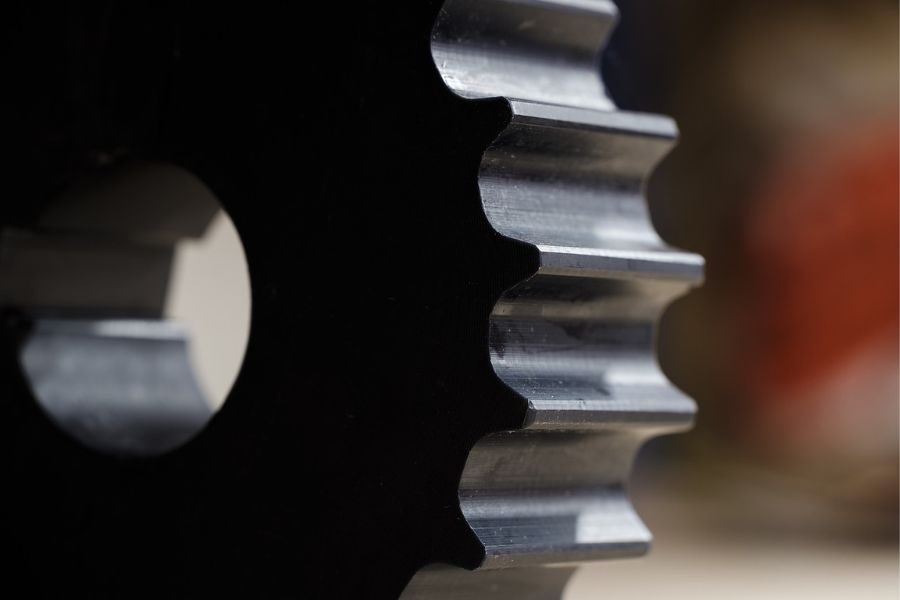

Creating complex internal cavities and fine details in difficult-to-machine materials

The EDM by EDM drilling Navarre, has established itself as a fundamental technique in precision machining. It offers advanced solutions for creating tiny, deep holes in conductive materials through a process based on the application of controlled electrical discharges. This has transformed manufacturing capability, especially in applications where accuracy and complexity are crucial.

How does it work?

During the process of EDM by EDM drilling Navarre, a specialized electrode is used to emit electrical discharges into a dielectric liquid. These discharges generate extreme heat that melts and vaporizes the workpiece material, creating precise, deep holes without direct physical contact. This method is ideal for creating complex internal cavities and fine details in more difficult-to-machine materials such as hardened steel or titanium. The precision and control of the process allow for the manufacture of components with extremely tight tolerances, essential for high-precision applications in industries such as aerospace, automotive and medical.

Machining of complex shapes

One of the main advantages of the EDM by EDM drilling Navarre Its unique feature is its ability to machine complex shapes that would be impossible to achieve using traditional methods. The technique allows for the creation of holes with very small and deep diameters and the process minimises the thermal impact on the workpiece, avoiding problems such as overheating and distortion, resulting in higher quality and precision in the finishes.

Multiple perforations in a single operation

The versatility of this technique is another of its great advantages. It is applicable to a wide range of materials, from the softest to the hardest, expanding the possibilities of design and manufacturing. This means that engineers and designers have the freedom to experiment with new materials and geometries without worrying about the limitations of the machining process. Drilling EDM not only offers precision and versatility, but also improves the efficiency of the production process. By being able to perform complex holes in a single operation, manufacturing times are reduced and operating costs are lowered. The ability to perform multiple holes in a single machine setup contributes to greater efficiency in series production, making this technique an attractive option for the manufacture of high-precision components.

If you are looking for advanced solutions for precision machining, the EDM by EDM drilling Navarre It is the ideal tool for complex drilling and machining, as well as internal cavities and fine details.