Discover the advantages of electrical discharge machining and its applications in key industrial sectors in Navarre.

The EDM It is a high-precision machining technology used in industrial manufacturing to cut and shape conductive materials. Its main advantage is the ability to work with extremely hard materials without direct contact, which minimizes wear and deformation of the parts. This technology has gained relevance in various industrial sectors that require high-precision and high-quality components. In this article, we'll tell you about the applications of EDM in some key industries and how a EDM company in Navarra can provide high-value solutions.

What is electrical discharge machining and why is it key to the industry?

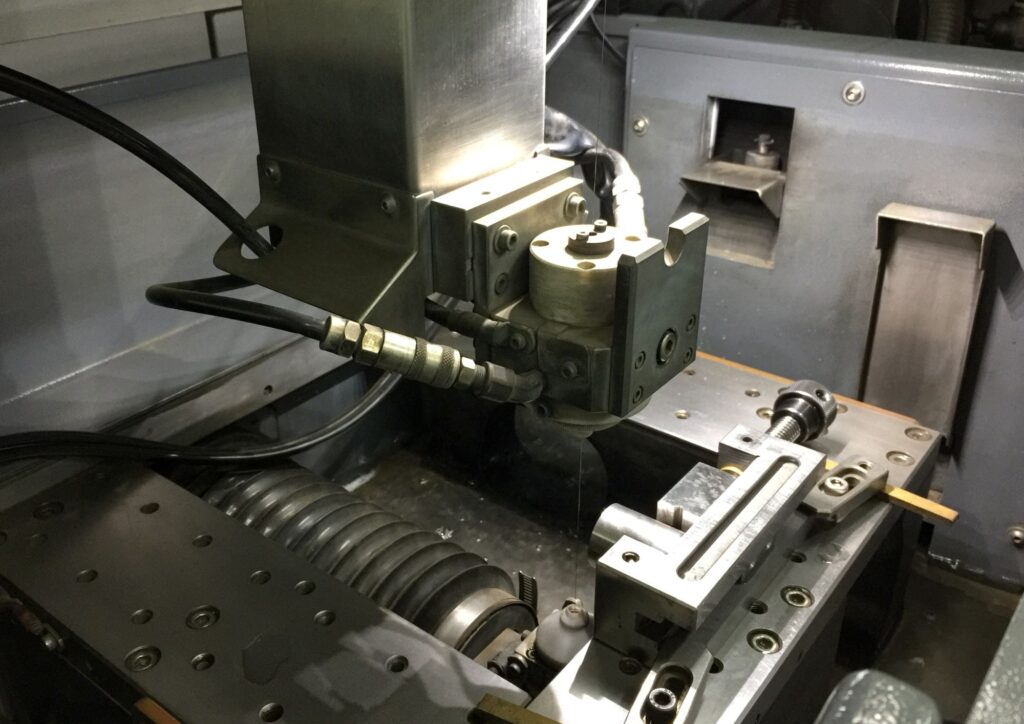

The EDM It is a machining process that uses electrical discharges to progressively erode the material. There are two main variants:

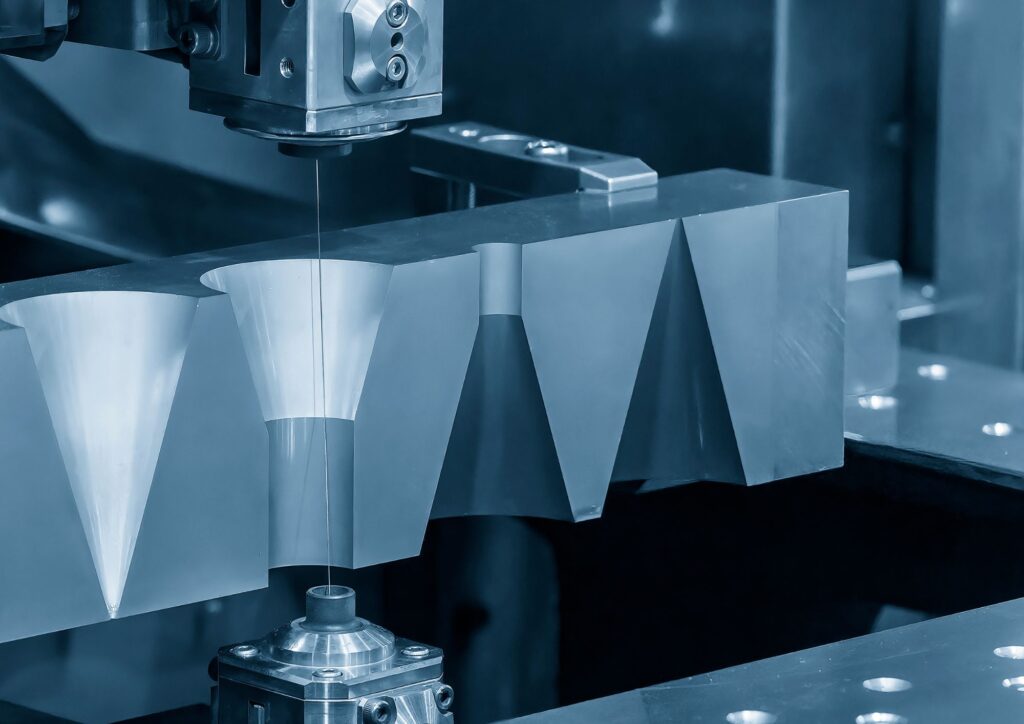

- Wire EDM: Uses a conductive wire to precisely cut complex geometries.

- Sinking EDM: It uses a specifically shaped electrode to create precise cavities in the workpiece.

This technology is essential in industrial sectors that require components with very tight tolerances. Thanks to its precision and ability to machine extremely hard materials, EDM is key in the manufacturing of parts for the automotive, aeronautical, and energy sectors.

Electrical discharge machining in the mold and die industry

The manufacture of molds and dies requires machining processes that guarantee high precision and durability. EDM It allows for impeccable finishes in injection molds and stamping dies, ensuring a perfect fit of the manufactured parts.

Some companies rely on EDM to produce high-quality tools, essential in the manufacturing of plastic, metal, and other materials. Its application guarantees longer mold life and reduced maintenance costs.

Applications of electrical discharge machining in the aeronautical and aerospace industry

In the aeronautical industry, the precision and strength of materials are crucial factors. Electrical discharge machining is used to manufacture engine, turbine, and aircraft structure components with extremely tight tolerances.

Materials such as titanium and high-strength alloys can be machined with EDM, allowing for complex cuts without compromising the structural integrity of the parts. Therefore, it is essential to have a EDM company in Navarra that facilitates the manufacturing of these components.

Electrical discharge machining for the automotive industry: high-precision components

The automotive industry also uses EDM to manufacture key parts, such as injectors, transmission components, and brake systems. This process produces high-quality surfaces and precise fits, ensuring optimal vehicle performance.

Furthermore, this type of machining contributes to optimizing production times and reducing costs in the manufacturing of metal components, making it a highly valued technology for companies in the sector.

Electrical erosion in the manufacture of medical devices

The medical industry demands extremely precise parts, especially in the manufacture of implants and surgical tools. EDM It allows machining titanium and stainless steel components without generating thermal stress, ensuring smooth and defect-free surfaces.

Electrical discharge machining in the energy and electronics industries

The high conductivity and precise cuts make EDM ideal for manufacturing electrical connectors and circuit board components. This process ensures precise machining of materials such as copper and its alloys.

In the renewable energy sector, the EDM It is used in the manufacture of components for wind turbines and solar panels. Its ability to cut complex parts with great precision improves the efficiency of these systems.

How to choose an EDM company in Navarra?

Select the best EDM company in Navarra requires considering several key aspects:

- Experience and specialization: A long history in the sector guarantees a high-quality service.

- Advanced technology: modern equipment allow for better results and greater efficiency.

- Certifications and references: Checking the company's reputation and success stories helps you make an informed decision.

Working with a specialized supplier ensures the production of high-precision parts, optimizing industrial production.

The EDM It is an essential technology, with applications in key sectors such as automotive, aeronautics, energy, and medical device manufacturing. Its ability to machine high-hardness materials with millimeter precision makes it an indispensable solution for industrial companies. Having a EDM company in Navarra specialized and with cutting-edge technology It is key to ensuring efficient processes and top-quality parts.