How industrial laser marking ensures exceptional accuracy when marking very small components

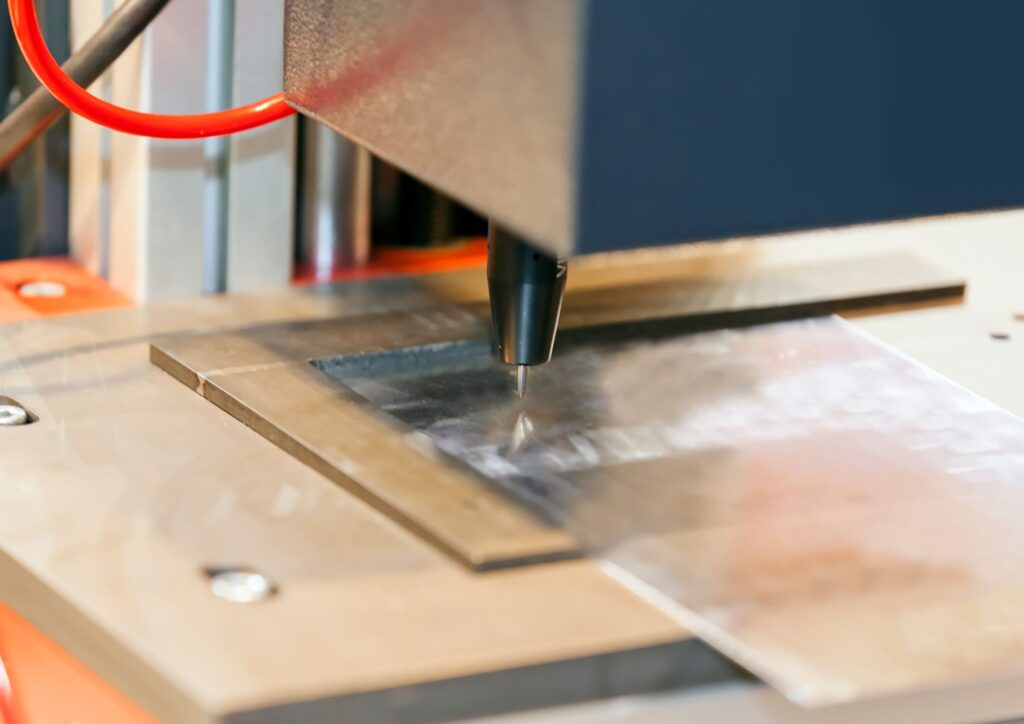

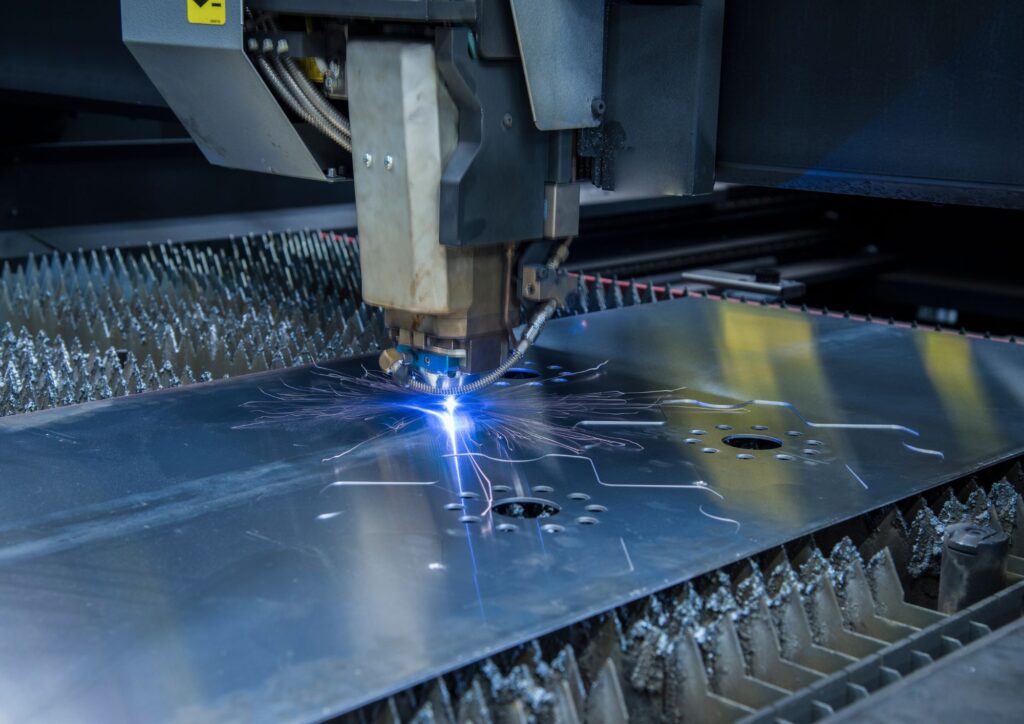

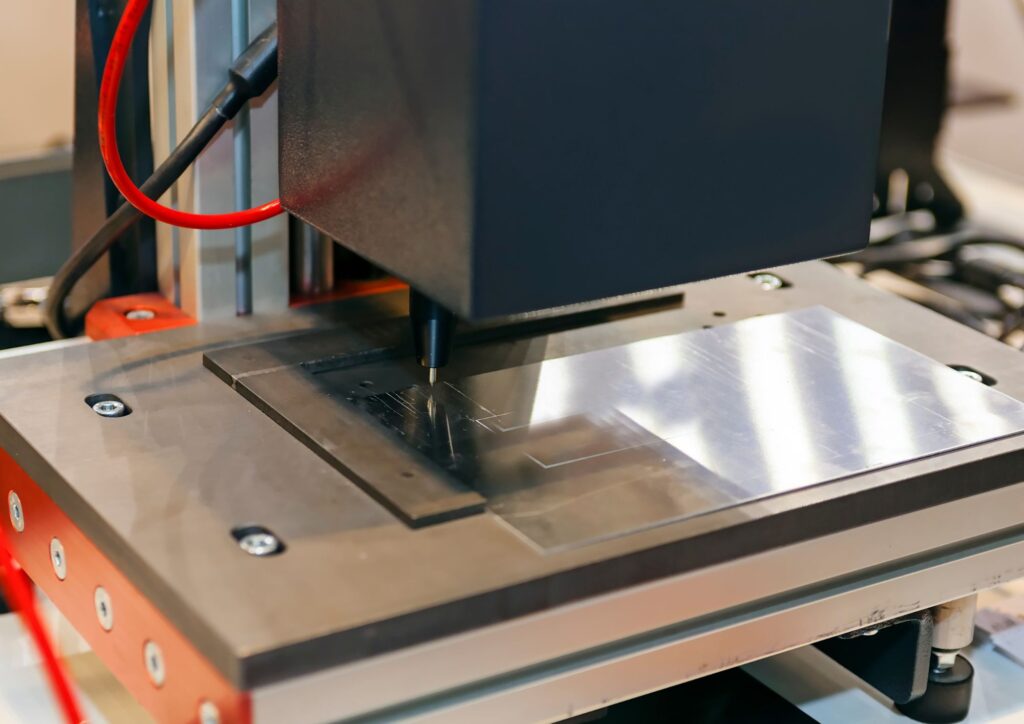

He industrial laser marking Laser marking is an advanced technology that uses a laser to engrave or mark material surfaces with millimetric precision. This technique is highly valued in various industries, especially when working with small parts, where precision is crucial. Laser marking is ideal for tiny parts, as it offers detailed results without compromising the integrity of the material.

In recent years, laser marking has gained popularity for its ability to make extremely fine and durable marks, making it a must-have option for companies looking for high precision in their products. With the advancement of this technology, new possibilities have opened up in sectors such as electronics, jewelry, automotive and many more.

What is industrial laser marking?

He industrial laser marking Laser marking is a process that uses concentrated beams of laser light to etch a mark into a surface. This mark can be a logo, serial number, manufacturing date, or any other relevant information. The process is performed without physical contact with the part, which minimizes the risk of damage and ensures that the marks are extremely accurate.

Laser marking systems use a variety of laser types depending on the material and the type of mark you want to generate. This technology is especially effective when it comes to small parts as it can work at incredibly high resolution, allowing tiny details to be marked with exceptional clarity.

Why laser marking is ideal for small parts

Laser marking is particularly suitable for small parts due to its ability to make marks with very fine resolution. The precision of the laser makes it possible to mark even the smallest surfaces with a level of detail impossible to achieve with traditional methods such as screen printing or mechanical engraving.

Among the main advantages of using industrial laser marking in small parts include:

- High resolution and detail: Allows for high-quality marking, even in tiny areas.

- Does not affect the integrity of the material: As it is a non-contact process, no deformations or alterations are generated in the piece.

- Durability: Laser markings are permanent and will resist wear, making them ideal for components that require long-term traceability.

Applications of laser marking in electronics

In the electronics industry, where precision and miniaturization are essential, laser marking has established itself as an indispensable tool. This technology allows critical information to be clearly and permanently engraved on tiny components, ensuring traceability, quality control and efficient production. Below, we explore its main applications and benefits.

Marking of electronic components: Manufacturers of microchips, circuits and other electronic components rely on this technology to mark their products with essential information, such as serial numbers, QR codes or traceability marks.

Benefits for traceability and quality control: The ability to mark parts with unique information ensures that each component can be tracked throughout its lifecycle, which is essential in inventory management and manufacturing process improvement.

Laser marking in jewelry: a solution for high-precision parts

Laser marking is widely used in the jewelry industry to create custom designs on rings, necklaces, and other accessories. This technology allows for intricate engravings on small pieces that would be difficult to achieve using traditional engraving techniques. This gives consumers the option to include details such as names, special dates, or unique symbols on their jewelry.

In addition to personalization, laser marking is also used in jewelry to ensure the authenticity of pieces. Many luxury brands use laser marking to engrave invisible codes or logos that can serve as proof of authenticity. This is crucial to combat counterfeiting and maintain consumer confidence in the market.

He industrial laser marking Laser marking is an efficient and accurate solution for companies looking to improve the quality and traceability of their products, especially when it comes to small parts. From electronics to jewelry, this technology is essential to ensure that parts are marked with the necessary level of detail without compromising their integrity. By choosing a specialized laser marking service, you can enjoy customized solutions that meet the highest standards of precision and quality.